Design solutions that enhance quality and safety

Damper Systems

Dampers are an important component of ventilation and smoke extraction systems. They are used in many different underground facilities such as road tunnels, railway tunnels and metro networks, as well as in the underground mining and marine industries.

Zitrón’s 50 plus years of providing complete ventilation solutions means that we have unparalleled experience in designing, manufacturing and installing dampers and smoke extraction systems in all types of installations.

Types of Dampers

Zitrón produces a wide range of dampers that can be tailored to the requirements of each application, including:

- Regulation dampers: These are used for ventilation systems that require a controlled airflow. These dampers have an opposite blade opening system that makes it possible to adjust the level of opening blades.

- Opening and closing dampers: These are used for total opening and closing systems. They have a parallel blade opening system that allows airflow as soon as the damper opens (fully opened/fully closed).

These dampers can be either horizontal or vertical, depending on their position in the individual ventilation system. They are fixed directly to the diffuser plate of the fan or to any other type of support using a fixing frame specially designed for this purpose.

Our dampers can be constructed from a variety of materials, including:

- Stainless steel: Used to manufacture base frames, blades and closing pieces, as well as for linkages, shafts, cams, flanges and other transmission elements. Finishes can be in AISI 304 or AISI 316, with A2 or A4 bolts.

- Galvanined steel: Used to manufacture base frames, blades and closing corners (S220GD + Z275), that are combined with linkages, shafts, cams bolts, etc. manufactured in zinc or stainless steel.

- Carbon steel: Used to manufacture base frames, blades and closing corners (S235JR) that are painted with polyester or epoxy and dried in furnace, and combined with linkages, shafts, cams bolts, etc. manufactured in zinc or stainless steel.

Depending on the construction type, Zitrón develops only heavy-duty dampers.

Accesories

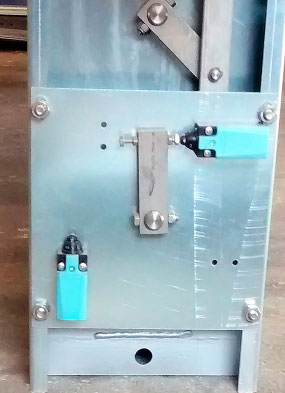

Zitrón has developed a wide range of accessories for dampers.

Actuators: Zitrón equips its dampers with the most reliable and precise actuators in the market, strong enough to guarantee accurate operation over many years. The different types of actuators are chosen in accordance with the customer’s requirements and can be electric, pneumatic or electro-hydraulic, with integrated control cabinet fitted in the ventilation system.

The actuator internal limit switches are used to control and stop the actuator when the damper is completely open or completely closed. Extra limit switches, torque switches, potentiometer, heater and other accessories can be included.

Actuator casings: In order to achieve an adequate thermal protection for the actuators, specially designed casings are provided, which ensure the actuator’s continuous operation, even in the most adverse conditions (250-400-600oC/ 1-2 hours). Zitrón provides actuators with either a flexible (textile jacket) or a rigid protection (ceramic case).

Other accessories provided by Zitrón are fixing frames, grilles or external limit switches.

Fire resistance certificates

Zitrón’s dampers are designed and manufactured in accordance with the most demanding regulations for ventilation projects and smoke extraction systems. Resistance tests carried out on our dampers include:

BS 476-20:

- Integrity 4 hours horizontal and vertical position.

400°C 2 Hours:

- Vertical and horizontal position.

400°C 1 Hour:

- Vertical and horizontal position.

UL-555:

- Cycling Test (20,000 full-stroke). Fire Endurance Test (2 Hours).

- EN 13501-4 Fire Classification

Performance rates and classifications

Zitrón’s products are tested to the applicable AMCA standards:

• Air Leakage (Class 1) in accordance with ANSI/AMCA standard 500D (silicone seal)

• Air Performance rating (Drop Test) in accordance with ANSI/AMCA standard 500D

Valves

Zitrón supplies a range of valves for underground ventilation systems

Round Single Blade Valve

Dampers in jet fans are installed in high-speed rail tunnels to protect impellers and blades from the piston effect. The high pressure due to the piston effect of the trains can damage the impeller and blades. In these circumstances, it is necessary to close the fan when the trains are in operation. The valve is motorized, and the motor is coupled with sensors inside the tunnel, so that when the train activates the sensor, a signal is sent to the valve in order to close it.

Butterfly and guillotine valves

To perform maintenance on fans, it is necessary to close the air circuit to stop the impeller. A motor, which can be either hydraulic or electric, is used to move a transmission to open or close valves. It is also important to install valves in the intake side to avoid the movement of the impeller when the access inspection door is open, thereby allowing the maintenance operations to be performed.

Related links

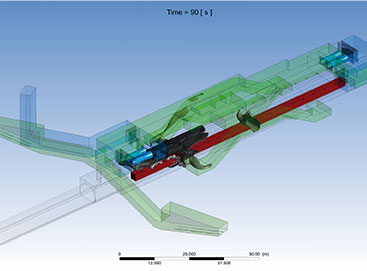

CFD simulations

Zitrón’s solutions are custom- designed using specific software to identify improvements and ensure the most efficient design.

DOWNLOAD BROCHURE

DOWNLOAD BROCHURE CONTACT US

CONTACT US FIND YOUR LOCATION

FIND YOUR LOCATION