The world’s largest Aerodynamic Test Bench for ventilation systems in underground environments

In a continuously changing market, where technical excellence and innovation are imperatives, Zitrón has demonstrated its commitment not only to innovation but also to quality. An indication of this commitment is its Test Bench.

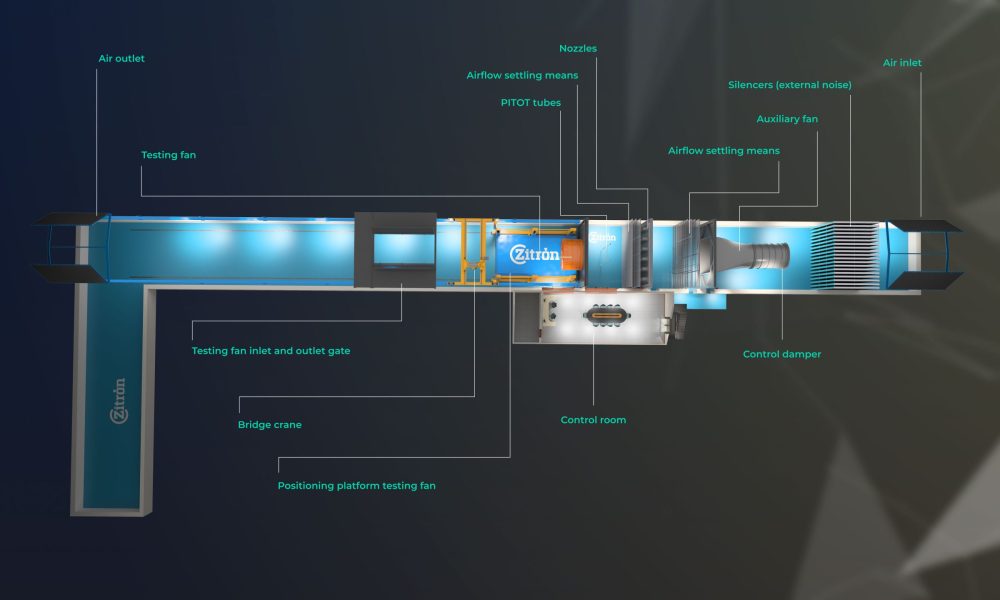

In 2004, Zitrón made the decision to design and build the world’s largest aerodynamic test bench for underground ventilation systems. This milestone posed a significant challenge for the company and brought about a considerable change in terms of quality and efficiency in the manufactured ventilation systems. This construction allows factory tests to assess the operation of fans with the aim of meeting the requirements specified by the customer through on-site testing. The system efficiency is analyzed at any point on the performance curve of a fan. This enables testing and recording of the stall region, enhancing the operational envelope of the fan.

Impressive Dimensions

This large-scale test bench extends over 100 meters and has a cross-sectional area of 52 square meters. It is capable of reaching an AN1 level of performance tolerance and enables the testing of fans with up to 2,500 kW and 5.8m diameter under simulated real operating conditions. certified as an Air Movement and Control Association International, Inc. (AMCA)* approved laboratory.

Its dimensions allow for full-scale testing of fans reproducing any ventilation circuit parameters – flow, pressure, efficiency, vibrations, temperature, etc. – specified by our customers. The testing parameters can cover not only the initial underground conditions, but also potential scenarios that might arise during the life of a project.

Its walls are made of concrete and has 600 mm thick. The total test bench volume is 5,145 m3. It has 7 levels with various meshes to achieve a stable flow. Additionally, A total of 30 nozzles with 16 intakes on each static pressure side facilitate the measuring of the differential pressure. It has setting chambers with air vent area of some 52.5 m2. These are just some of the most prominent features, including the automatic determination of the stalling area and a self-leveling, fan positioning platform.

Continuous Commitment to Quality

From its origins, it can be said that what truly makes Zitrón exceptional is its continuous commitment to quality and innovation. In addition to this test bench, Zitrón continues to research and design systems to assess the efficiency of its products. An example of this is its testing tunnel, which allows for the analysis of ventilation system behavior in response to the piston effect in high-speed train installations. Zitrón’s dedication to staying at the forefront of underground ventilation technology demonstrates its customer-centric approach and determination to provide superior solutions.